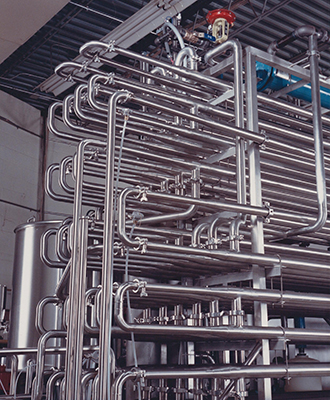

TUBULAR ASEPTIC PROCESSING SYSTEMS

Properly operated and maintained, Excel-A-Tec’s tubular aseptic processing systems are engineered with features to help our customers process their products with many benefits. They are engineered to resist burn-on, deposit and contamination which can lead to longer running times and can maintain product quality and flavor. Excel-A-Tec’s energy-efficient systems are unitized, preassembled, prewired and factory dry pretested before shipment from our plant which can assist in a faster and more efficient start-up.

Properly operated and maintained, Excel-A-Tec’s tubular aseptic processing systems are engineered with features to help our customers process their products with many benefits. They are engineered to resist burn-on, deposit and contamination which can lead to longer running times and can maintain product quality and flavor. Excel-A-Tec’s energy-efficient systems are unitized, preassembled, prewired and factory dry pretested before shipment from our plant which can assist in a faster and more efficient start-up.

Excel-A-Tec’s systems are engineered to process a wide range of products for: aseptic/Ultra-High Temperature (UHT), pasteurization, ultra-pasteurization, extended shelf life and hot fill applications. Engineered to meet government requirements, our systems are available in a wide variety of sizes and capacities to meet our customers’ needs:

LAB SYSTEM

• Engineered for capacities from 0.5 liters/minute up to 5 liters/minute

• Designed with coil heat exchangers

SINGLE TUBE SYSTEM

• Engineered for capacities from 40 GPH to 1,500 GPH

• Designed with coil heat exchangers

PATENTED* BALL INJECTION/RECOVERY SYSTEM

• Engineered for capacities from 5 GPM to 25 GPM

• Designed to save expensive product at the interface of product and water

MULTIPLE TUBE SYSTEM

• Engineered for capacities from 1,000 GPH to 11,000 GPH

• Designed with patented* multiple tube-in-tube hairpin heat exchangers

• Designed for products with pulp and small particulates up to 8 mm